| Sign In | Join Free | My portofva.com |

|

| Sign In | Join Free | My portofva.com |

|

| Categories | Pressure Thermoforming Machine |

|---|---|

| Brand Name: | HengXing |

| Model Number: | HX-76HD |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | USD:6999 $ (deposit) |

| Payment Terms: | D/A,L/C,D/P,Western Union,MoneyGram |

| Delivery Time: | 45 work days |

| Packaging Details: | wooden case |

| model: | HX-76HD |

| Applicable sheet materials: | PVC、PP、PE、POF、PPT、PTGF、APET、ABS、OPP、PS、PET |

| Forming length: | 1220 mm |

| Forming width: | 420-710mm |

| Material thicknes: | 0.1-2.5mm |

| Working speed: | 1-10 times/minute |

| Overall weight: | Approximately 3000KG |

| Machine dimensions: | L7350×W1770×H2700mm |

| vacuum pump: | Cosmic star 200m ³/H |

| Electric furnace power: | Maximum 39KW |

| Company Info. |

| Hengxing Blister Machinery (Shenzhen) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

HX 76HD Pressure Thermoforming Machine Efficient Demolding

Product Description:

Various types of films (PVC, PP, PE, POF, PPT, PTGF, APET, ABS, OPP, PS, PET, etc.) can be vacuum molded into plastic covers of different shapes through different molds, such as toys, hardware, food, electronics, pharmaceuticals, daily necessities, clothing, as well as ceiling panels, wall panels, cake boxes, automotive materials, and sanitary materials with three-dimensional relief patterns, forming exquisite inner lining and outer packaging, making products refreshing and improving competitiveness.

special function:

1. Multi-mode vacuum regulation: suitable for various product

forming needs

In response to the differentiated requirements of vacuum action

time for products with different structures and materials, the

equipment is designed with a triple adjustment mode of delayed

vacuum, primary vacuum, and secondary vacuum: the vacuum start

timing and duration can be flexibly set according to product

characteristics (such as deep cavity structure, thin-walled

material), ensuring that the plastic sheet is uniformly stressed

and tightly adhered to the mold during the molding process,

avoiding product deformation, bubbles, and other problems caused by

improper vacuum adjustment, covering the molding needs of products

from simple to complex.

2. Efficient demolding solution: Overcoming the difficult demolding

problem of high difficulty products

For the industry pain points of difficult demolding of high

difficulty products (such as irregular structures and deep cavity

designs), the equipment is equipped with dual demolding technology:

Multiple bottom air demolding: By using multiple pulse bottom air

blowing, gradually loosen the bonding surface between the product

and the mold to avoid product damage caused by one-time demolding.

Pre-demoulding and blowing: Pre-set the blowing program before the

demoulding action starts, forming an air gap between the product

and the mold in advance to reduce demoulding resistance. The

combination of the two can efficiently solve the problem of

difficult demolding of high difficulty products, improve the yield

rate, and ensure production continuity.

3. Rapid heating technology: Shorten preheating time, save energy,

and reduce consumption

The device achieves dual breakthroughs in heating efficiency and

energy consumption control, greatly optimizing the startup process:

Rapid preheating: The electric furnace can enter production mode

within 5 minutes of overall preheating. The latest energy-saving

heating brick only needs 1 minute of rapid preheating, and then

stabilizes at a constant temperature for 2-3 minutes before it can

be officially produced (traditional old electric furnace preheating

takes about 20 minutes), significantly reducing the waiting time

for start-up and improving the effective production time per day.

Energy saving advantages: The new energy-saving heating brick saves

about 20% of electricity compared to traditional heating bricks,

and long-term use can significantly reduce the energy consumption

cost of enterprises, combining efficiency and economy.

4. General control voltage regulation system: precise temperature

control, easy operation

Adopting a dual stage temperature control design of "master

control+independent", balancing temperature control efficiency and

flexibility:

Main control module: One main temperature control module can

simultaneously manage the basic temperature settings of 60 heating

bricks, reducing repetitive operations and improving parameter

setting efficiency.

Independent temperature regulation: 60 heating bricks support

independent temperature adjustment, which can accurately adapt to

the heating needs of different areas of the electric furnace (such

as near the edge and center of the mold), avoiding uneven product

molding caused by local high or low temperatures.

5. Temperature probe monitoring: Real-time monitoring of

temperature control status inside the furnace

Equipped with high-precision temperature probes to achieve visual

management of furnace temperature:

Real-time display of the actual temperature inside the furnace,

visually observing whether the electric furnace has reached the

preset constant temperature state, facilitating operators to adjust

parameters in a timely manner.

To avoid heating instability caused by temperature control blind

spots and provide a reliable temperature basis for the production

of products with different materials (such as PLA requiring precise

constant temperature and PET requiring high temperature stability),

ensuring batch production consistency.

6. Front and rear dual spray silicone oil device: balancing

demolding and anti-static requirements

Design segmented spraying functions for different stages of sheet

processing to improve product quality and processing convenience:

Front-end spraying (cow's milk solution): Spray cow's milk solution

before the sheet enters the forming process to enhance the surface

lubrication of the sheet, reduce the adhesion between the formed

product and the mold, and assist in easy demolding.

Back-end spraying (anti-static liquid): After the sheet is formed

and processed, anti-static liquid is sprayed to effectively

eliminate static electricity on the surface of the sheet and

prevent dust adsorption or static electricity from affecting

electronic products (such as electronic tray packaging) in

subsequent processes.

7. Secondary molding function: ensuring demolding quality and

optimizing product form

Add a secondary upper mold action in the demolding process to

improve product forming accuracy and integrity:

During demolding, additional pressure is applied through secondary

molding to assist in separating the product from the mold and

reduce the difficulty of demolding. On the other hand, slight

shaping can be applied to the edges and details of the product to

avoid deformation during demolding, ensuring a more perfect shape

and precise size of the finished product.

8. Rapid molding technology: breaking through the bottleneck of

difficult product vacuum forming

Develop rapid molding technology for products with complex

structures and high difficulty in forming, such as multi-cavity and

deep stretching products

By optimizing the driving structure and pressure control logic of

the upper mold, precise and rapid response of the upper mold action

can be achieved, ensuring that the sheet can quickly adhere to the

mold after heating and softening, and reducing the shape deviation

of the sheet before cooling and hardening.

Effectively solve the problems of "loose fitting and poor detail

molding" in the process of high difficulty product vacuum forming,

and broaden the processing capability of the equipment for complex

products.

9. Delayed cold air and water spray: accelerates cooling and

improves production efficiency

Through active cooling design, the cooling cycle of the product is

shortened, helping to improve production speed:

Delayed cold air: Delay the start of the cold air system after the

product is formed, continuously taking away the surface heat of the

product and accelerating the solidification and shaping of the

product.

Spray cooling: For products with thick walls or slow thermal

conductivity, the spray function can be activated to quickly cool

down through water mist, further shortening the cooling time. The

combination of the two can significantly increase the production

quantity per unit time and adapt to the needs of large-scale mass

production.

10. Vibration demolding: Efficient production of difficult

products, ensuring demolding safety

Specially designed for high difficulty products (such as deep

cavities and irregular curved surfaces) with vibration demolding

function:

During demolding, high-frequency and low-amplitude vibrations are

used to gradually break the adhesion between the product and the

mold, avoiding product damage or mold damage caused by forced

demolding.

The vibration parameters can be flexibly adjusted according to the

characteristics of the product, which can ensure safe and rapid

demolding, as well as ensure the integrity of the product form, and

improve the production stability and yield rate of difficult

products.

11. Sheet pulling: optimizing material utilization and reducing

loss costs

To address the issue of material waste during sheet processing,

design a sheet retraction function:

During production gaps or mold changes, the reverse recycling of

sheets can be controlled to avoid excess cutting losses caused by

excessive sheet transportation.

Effectively improving the utilization rate of sheet materials,

minimizing raw material waste, and promoting long-term use can

significantly reduce material costs for enterprises and enhance

production efficiency.

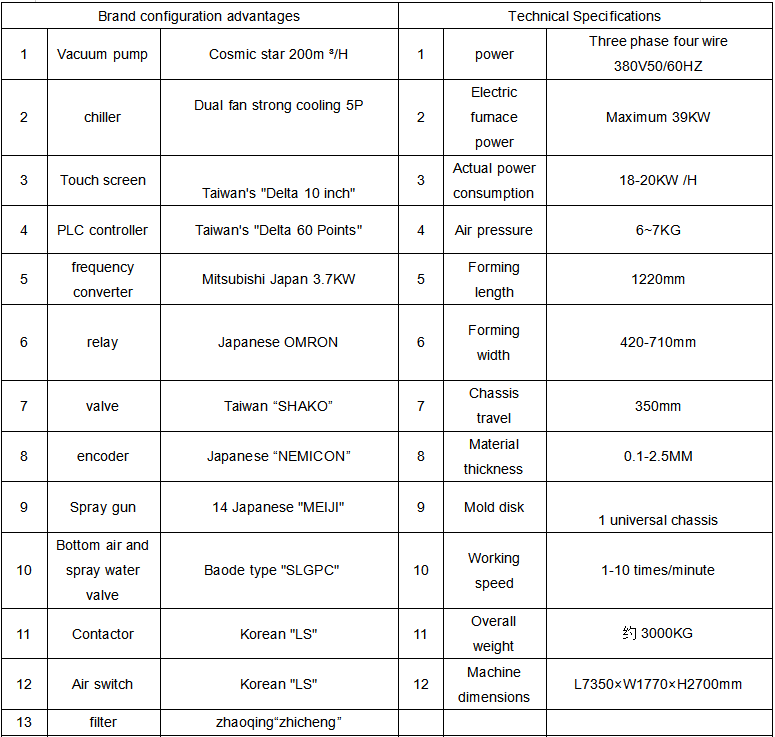

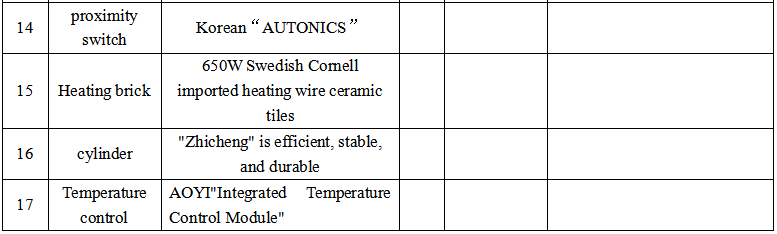

Machine Parameters:

|