| Sign In | Join Free | My portofva.com |

|

| Sign In | Join Free | My portofva.com |

|

| Categories | Waste Baler Machine |

|---|---|

| Brand Name: | Xrido |

| Model Number: | Customizable |

| Certification: | CE ISO TUV |

| MOQ: | 1 set |

| Delivery Time: | 5-30 word days |

| place of origin: | Henan, China |

| video outgoing-inspection: | Provided |

| machinery test report: | Provided |

| core components: | Bearing, Gearbox, motor, Pressure vessel, Gear |

| model number: | Y81F-400A |

| warranty: | 1 Year |

| material / metal processed: | Brass / Copper, Alloy, Carbon Steel, Stainless Steel |

| key selling points: | Long Service Life |

| Product name: | Metal Scrap Iron Aluminum Baler |

| Baler Density: | >=2000 kg/m 3 |

| Single Circling time: | 120minute |

| Baler Size: | 600*600 mm |

| Packaging Material: | Paper, Plastic, PET bottle |

| Type: | Hydraulic Metal Baler |

| Overall size: | steelmaking plant. recycling processing and metal smelting industry. |

| Compression Chamber Size: | 20500*2000*1200 mm |

| Bale discharging mode: | Turn over/Side push |

| Condition: | New |

| Marketing Type: | Hot Product 2019 |

| Warranty of core components: | 1 Year |

| Applicable Industries: | Garment Shops, Building Material Shops, Machinery Repair Shops, Restaurant, Food Shop, Construction works |

| Showroom Location: | None |

| Company Info. |

| Henan Xrido Environmetal Protection Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Metal baler is a kind of mechanical equipment, which is mainly used to compress, compact and shape various waste or recycled metal materials to achieve reduction, storage and transportation.

Its performance is reflected in the following aspects:

1. Strong pressure regulation ability: through hydraulic system control, it can adjust the appropriate pressure according to the different types and states of metal materials to ensure high packing density without damaging the raw materials.

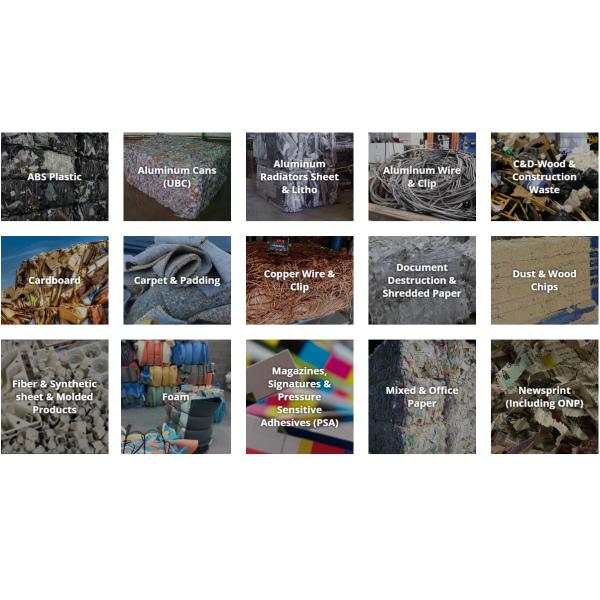

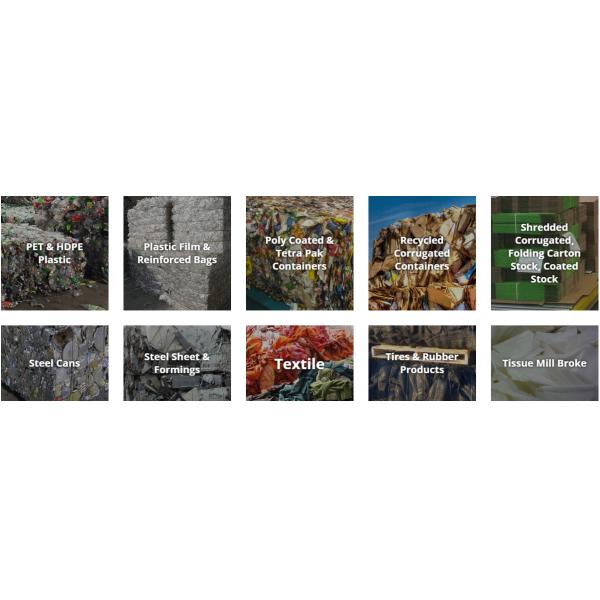

2. Wide adaptability: It can pack various types of scrap steel, aluminum, copper, iron and other metal materials, with good versatility and flexibility.

3. Production: The use of automated operation and continuous working mode greatly improves the working speed and production efficiency of metal packaging and reduces labor costs.

4. Good equipment stability: Made of wear-resistant and corrosion-resistant materials, it has a compact structure, stable operation, low failure rate and long service life.

5. Environmental protection and energy saving: The dust and noise generated during the baling process are effectively controlled, in line with national environmental protection standards, while low energy consumption, which is conducive to energy conservation and emission reduction.

Model | Nominal force(KN) | Chamber size(mm) | Baler size(mm) | Capacity(KG/H) | Single cycle time(s) | Motor power(KW) |

XRD-125A | 1250 | 1200x700x600 | 300x300 | 1200-1800 | <=100 | 15 |

XRD-135A | 1350 | 1400x900x700 | 350x350 | 1800-2200 | <=110 | 22 |

XRD-160 | 1600 | 1400x900x800 | 350x350 | 2000-2800 | <=120 | 22 |

XRD-160A | 1600 | 1600x1000x800 | 400x400 | 2000-3500 | <=120 | 22 |

XRD-160B | 1600 | 1600x1200x800 | 400x400 | 2200-4000 | <=130 | 30 |

XRD-200A | 2000 | 1600x1200x800 | 450x450 | 2500-4500 | <=130 | 30,37 |

XRD-250A | 2500 | 1800x1200x900 | 500x500 | 4000-6000 | <=140 | 44,60 |

XRD-250B | 2500 | 2000x1400x900 | 500x500 | 5000-6300 | <=150 | 44,60 |

XRD-315A | 3150 | 2000x1400x1200 | 500x500 | 5000-6500 | <=150 | 60,74 |

XRD-315B | 3150 | 2000x1750x1200 | 600x600 | 5000-7000 | <=160 | 60,74 |

XRD-315C | 3150 | 2400x2000x1200 | 600x600 | 6000-7500 | <=160 | 74 |

XRD-400B | 4000 | 2400x2000x1200 | 600x600 | 7500-9000 | <=160 | 90 |

Types of metal briquetting balers

Depending on the structure, function and application scenario,

metal briquetting balers can be divided into many types. Among

them, according to the pressure size, they can be divided into

small, medium and large briquetting machines; according to the

packaging method, they can be divided into vertical, horizontal and

side briquetting machines; according to the degree of automation,

they can be divided into manual, semi-automatic and fully automatic

briquetting machines.

Final Products

|